Harness the Strategic Edge of Concrete Scanning for Unparalleled Project Success and Quality Control

In the realm of modern building and construction and infrastructure growth, the usage of concrete scanning innovation has become an essential tool for guaranteeing job success and maintaining high quality standards. This innovative method uses a critical side by supplying necessary insights into the structural stability of concrete components, therefore enabling informed decision-making throughout the job lifecycle. By diving into the midsts of concrete make-ups and revealing concealed abnormalities, stakeholders can proactively address possible risks, improve procedures, and maximize resource appropriation. The true power of concrete scanning exists not only in its ability to boost job end results but also in its ability to change traditional methods, setting a new benchmark for accuracy and performance in the building industry.

The Value of Concrete Scanning

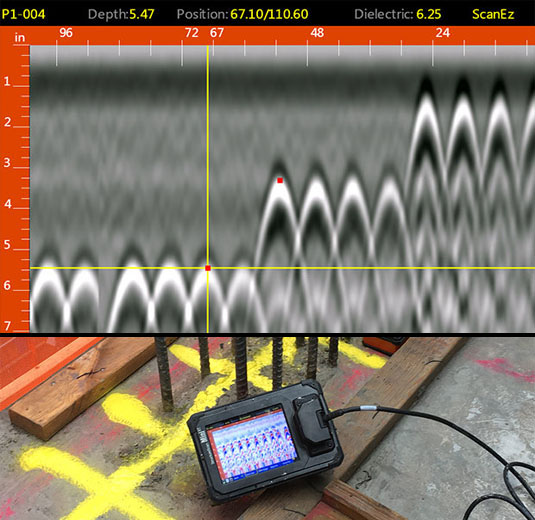

Concrete scanning is an important step in building tasks to guarantee the security and stability of frameworks. By making use of different scanning modern technologies such as Ground Penetrating Radar (GPR) and electro-magnetic induction, building and construction groups can non-destructively examine the subsurface of concrete frameworks to recognize possible dangers like rebar, channels, or post-tension cables. This info is critical for job professionals, designers, and supervisors to make enlightened choices and avoid expensive mistakes throughout the building and construction procedure.

One of the main reasons why concrete scanning is so crucial is its ability to avoid mishaps and injuries on the building site. Inadvertently cutting with a live electrical channel or damaging post-tension cables can have disastrous consequences, not only in regards to safety but likewise in regards to project hold-ups and financial implications. By carrying out detailed concrete scanning before any boring, reducing, or coring tasks, building and construction groups can alleviate risks and produce a safer working atmosphere for everybody included.

In addition to safety and security factors to consider, concrete scanning also plays a key duty in making sure the lasting durability and high quality of the framework. By discovering any kind of anomalies or issues concealed under the surface area, such as gaps or delamination, early treatment can be executed to deal with these concerns prior to they escalate into even more considerable problems. Eventually, spending in concrete scanning is a proactive procedure that can conserve time, money, and resources in the long run, while likewise promoting the greatest criteria of construction excellence.

Advanced Innovation for Specific Outcomes

By incorporating these sophisticated technologies into concrete scanning methods, construction teams can simplify workflows, minimize task hold-ups, and ensure the general quality and success of the task. The accuracy and performance provided by these tools add substantially to the job's success by assisting in notified enhancing and decision-making high quality guarantee actions.

Enhancing Task Effectiveness and Timelines

Moreover, concrete scanning allows teams to determine structural weak points and prospective risks beforehand, enabling punctual removal and stopping mishaps that could derail job timelines. The real-time data supplied by scanning devices assists in informed decision-making, causing smoother sychronisation among different trades and stakeholders. This enhanced cooperation reduces conflicts, enhances performance, and inevitably speeds up task shipment.

Moreover, by proactively dealing with problems with concrete scanning, building and construction groups can follow routines better, decrease downtime, and optimize resource appropriation. The ability to find covert barriers and validate architectural integrity effectively contributes to overall project efficiency and timelines, making certain successful results and client contentment.

Ensuring Safety and Threat Reduction

Risk mitigation methods can be enhanced through the in-depth details given by concrete scanning, enabling task groups to make educated choices that minimize the chance of unforeseen occurrences. Furthermore, by properly drawing up subsurface problems, professionals can avoid expensive rework, hold-ups, and damages to existing frameworks, better adding to overall task safety and success. Implementing concrete scanning as a regular practice not just guarantees a much safer workplace but also imparts confidence in stakeholders pertaining to the job's commitment to quality and threat management.

Quality Control Via Concrete Scanning

Concrete scanning plays a crucial duty in maintaining high quality guarantee requirements within building tasks. By making use of advanced scanning modern technologies such as Ground Permeating Radar (GPR) and Concrete X-ray, task supervisors and designers can ensure the honesty and quality of concrete structures. With concrete scanning, potential problems, such as gaps, fractures, or reinforcing bar blockage, can be discovered non-destructively, enabling timely treatments to maintain the architectural honesty of the project.

Quality guarantee via concrete scanning not just assists in recognizing existing concerns however also enables positive measures to avoid future troubles that can jeopardize the safety and longevity of the structure. By conducting extensive scans at essential article phases of building, groups can confirm the accuracy of architectural strategies, confirm the positioning of vital elements, and deal with any kind of deviations immediately. This aggressive method lessens rework, decreases pricey hold-ups, and inevitably brings about the shipment of top notch, resilient structures that surpass or meet industry requirements.

Conclusion

In conclusion, concrete scanning plays an important duty in making sure job success, safety, quality, and performance guarantee. By utilizing advanced modern technology for precise results, construction projects can be finished with higher accuracy and within timelines. The calculated side offered by concrete scanning permits for proactive threat mitigation and improves general project monitoring. Including concrete scanning right into building and construction procedures is essential for accomplishing unparalleled success and making sure quality end results - RainierGPR Concrete Scanning.

In the world of contemporary building and construction and facilities growth, the usage of concrete scanning technology has arised as a click reference critical device for making sure project success and maintaining quality requirements. By incorporating these sophisticated technologies right into concrete scanning techniques, construction groups can simplify workflows, minimize task hold-ups, and guarantee the overall quality and success of the job.Offered the imperative nature of task performance and timelines in building and construction monitoring, the focus currently moves in the direction of ensuring safety and security and mitigating risks within the job atmosphere.Concrete scanning plays a crucial duty in maintaining high quality guarantee requirements within building and construction tasks. By utilizing sophisticated scanning modern technologies such as Ground Penetrating Radar (GPR) and Concrete X-ray, task supervisors and engineers can ensure the stability and high quality of concrete structures.